Watch Case Production Flow

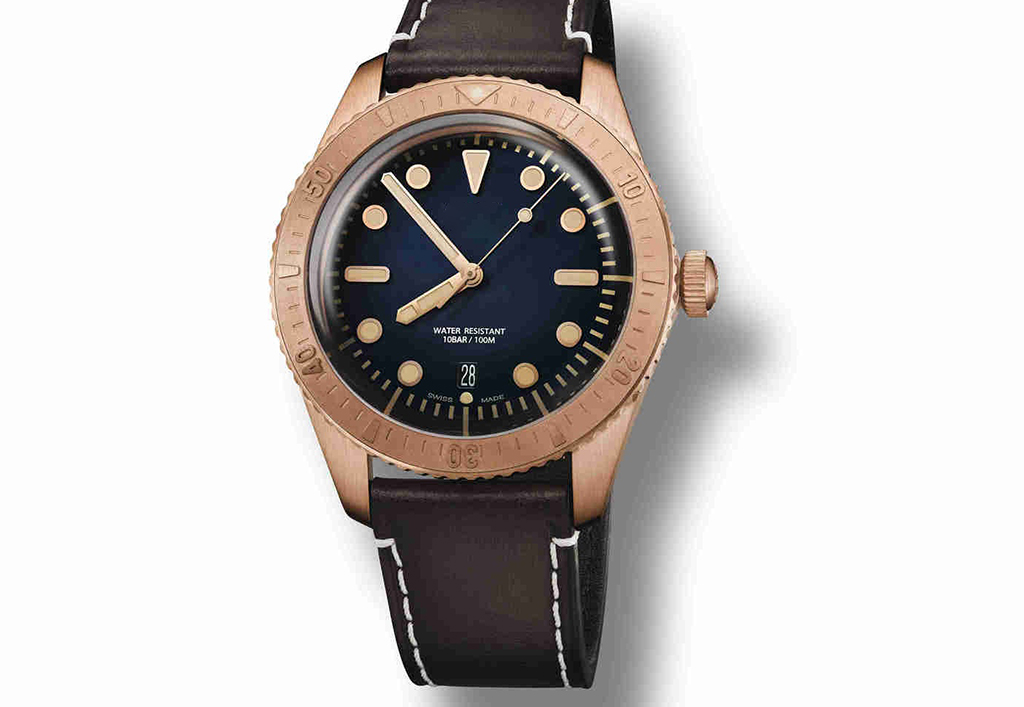

At present, the domestic market case by brass, copper alloy, steel, tungsten steel case.

1.Alloy case: Generally speaking, the processing technology is simple, the production cycle is short, the output is large, the price is low, and the development in recent years is relatively rapid. But because of its water resistance, wear resistance, corrosion resistance and many other aspects of the lack of large celebration activities rarely used, generally used in beer, beverages and other aspects of the promotion. It belongs to middle and low price watches.

2.Brass Case: shell has the advantages of easy processing, beautiful appearance, good waterproof performance, surface wear and corrosion resistance and other advantages. Many manufacturers use them more. Its moderate price is also its advantage. Belongs to the high, middle class watches.

3.Steel case: general processing complex, output is small, the price is high, its performance is better than that of alloy shell and shell, generally used for high-grade electronic watches and mechanical or automatic mechanical watches. It belongs to high-end watches.

4 .Tungsten steel case: machining difficult, not easy to wear, and with a sapphire watch, Japan movement, tungsten steel watchband. This watch is usually a high-end electronic watch.

Now most factory is the first line of cutting embryo assigned, if the guest to return after OK to mold the embryo

Embryos are divided into fine embryos and rough embryos. After the fine embryo comes back, it can only be processed very little, and some can be milled in rice,

There is a hole in the screw. And the rough embryo doesn't need me to explain

The processing process of a watch case is divided into three parts:

1. Machine processing, that is, cutting, cutting, including the car, milling, drilling, and now more popular CNC processing technology. Highest technical content

2.The mill is mainly used to machine mill processing, the appearance of grinding is the core technology of high-end table. Asking for experience.

3. The last one is packaging, that is, playing glass, Pakistan tube, the lowest technical content

2F, Building A, Shimei Industrial Park, Dalang Town, Longhua District, Shenzhen, China