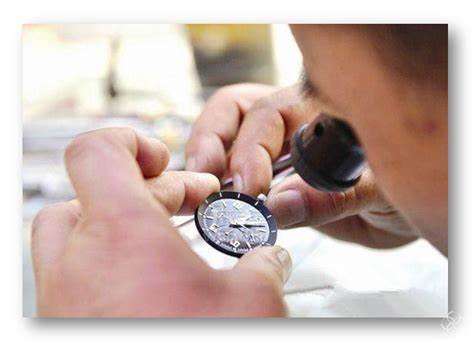

Which parts cost more when customizing a watch? Many people will encounter such a problem. When customizing a watch, they do not know the cost of each part in the watch, which often leads to exceeding the budget. How to solve this problem? Looking for a watch manufacturer to understand the cost ratio of watch processing parts is more conducive to planning your budget so that you can accurately locate the watch style and the corresponding consumer market.

Watch brands have found many watch factories for watch assembly and processing, but the structure and composition of watches and the proportion of processing and production costs are not very clear. Accurate cognition, as a manufacturer of Giantwatch with many years of experience in the watch industry, will discuss this with you.

When the watch is assembled and processed, the five parts of the mirror, the case, the strap, the inner ring, and the dial are processed separately. The hands, the buckle, and the bottom cover are called small parts, while the core power of the watch movement is separate. Procurement of finished products through professional watch movement factories for assembly and processing.

Protect the watch movement from external dust, water, and vibration damage. At present, the market mainly adopts alloy shells, copper shells, steel shells, tungsten steel shells,s and so on. The most expensive is the tungsten steel shell, then the copper shell, and then the steel shell, and the lowest cost is the alloy shell.

Dial protection is usually made of plexiglass, sapphire, and minerals. Among them, sapphire glass has the highest cost. The processing and production cost of good sapphire glass is higher. If it is required to have an R arc, the processing cost will be higher because This kind of processing scrap rate is much higher than that of ordinary sapphire glass lenses, thereby increasing the processing cost.

It is mainly used to display the time. It is mainly responsible for the style and appearance of the watch. Whether a watch looks beautiful or not depends on it. Commonly used materials such as copper, aluminum, and paper are used for processing. The cost is lower than that of the case and the mirror, mainly to test the style design ability of the dial.

There are two kinds of belts and metal chains. The choice of the strap is generally to match the case, and what kind of case material is selected depends on what kind of strap is selected. Generally speaking, the processing cost of the strap made of the metal chain is definitely higher than that of the belt material.

Mainly made of stainless steel and titanium, it is divided into folding buckles, butterfly buckles, double safety buckles, etc. The assembly and processing cost of the watch is second to that of the strap, and the price depends on the material that needs to be made. Titanium is more expensive than stainless steel.

Used to lock the watch mirror, it can be divided into two types: fixed type and one-way rotating type. It does not belong to the five major parts of watch assembly and processing, so the processing cost is not high.

The hands are an important part of the display of the hours, usually the hours, minutes, and seconds. The production and processing costs of small watch parts are also not high.

2F, Building A, Shimei Industrial Park, Dalang Town, Longhua District, Shenzhen, China